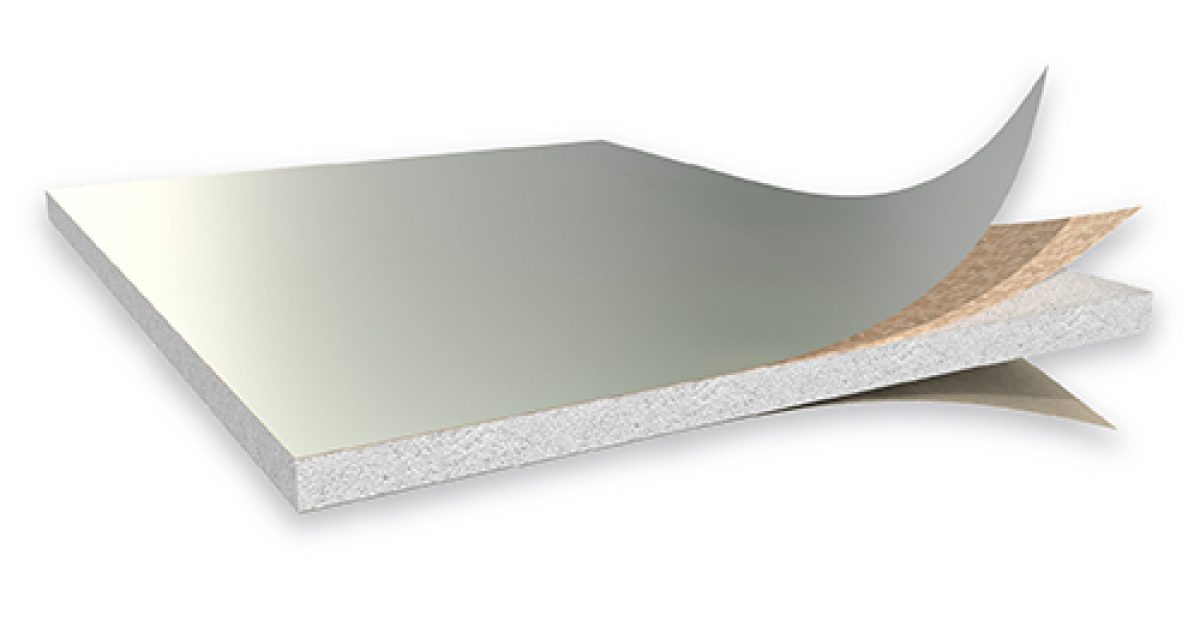

What You Need To Know About Drywall/Sheetrock To Improve Your Home’s Quality and Function—BYHYU 2482/9/2022 It’s honestly pretty hard to get excited about drywall. Drywall is a subject that’s kinda, well… dry. But drywall is a material that goes in just about every space of the house, so we want to be able to make informed decisions about what type of drywall we should request to make our walls last longer and perform better. I won’t go into too much boring detail, but I’m hoping to give you enough information so you can have an intelligent conversation with your builder or drywall contractor, and so you will know the best type of drywall for different areas of your house. Despite what you might think, all drywall isn’t the same. Let’s start by defining a couple of pro terms to give us a good foundation for the rest of the lesson. PRO TERMS: Plaster and Drywall Plaster starts as a dry powder made of lime or a mineral called gypsum plus sand. It’s then mixed with water to form a stiff but workable paste that is applied to a wall surface. In residential construction, the surface to which the plaster paste is applied is most often made of lengths of wood called lath which is nailed to wall studs. Several coats of plaster are typically applied to the lath surface to create the finished wall. The multiple coats required for plaster make plaster more labor intensive than drywall. Plaster not only takes more time and effort to apply as compared to drywall, but it also requires significantly more skill. And unfortunately the number of skilled plaster laborers is dwindling. Plaster is most often found in homes built before World War II, but occasionally homeowners request plaster for their new builds, especially if they are building a historical style or an estate type home. Plaster, when done well, can look more high end than drywall, but it’s more difficult to hang artwork and mirrors on plaster and plaster is challenging to repair. Because plaster requires more skill and time to complete, the labor for plaster walls usually costs three times as much, or more, than drywall installation. However, the material costs for plaster and drywall are pretty similar. Drywall is a flat panel made of gypsum plaster sandwiched in between two sheets of thick paper or some other material. So instead of having to mix and apply the plaster paste to walls like you would with plastering, drywall is prefabricated plaster board with some sort of covering. Drywall panels are attached to metal or wood studs using nails or, preferably, screws. Sheetrock is a specific brand of drywall, but the two terms are often used interchangeably. Drywall is also called wall board, plaster board or gypsum board. Since the vast majority of new builds use drywall instead of plaster, our mini lesson will focus on drywall. Before we move into the meat of the lesson, I gotta thank Blaxative who gave us our latest Apple Podcasts rating and review. They say the show is great for new homeowners, for people who want to renovate their house themselves or through a contractor. Thanks Blaxative for telling potential listeners that the show can be helpful for not only those building new houses, but also for people buying and remodeling homes. I appreciate you for supporting the show. Okay, let’s talk more in depth about drywall. Drywall comes in four common thicknesses, each used for different reasons. 1/4-inch Drywall Quarter inch drywall is the thinnest of all the options. It’s most commonly used as a skimming material in remodels. Quarter inch drywall can be mounted over existing walls to hide imperfections and give the house a fresh new look. Some quarter inch drywall is flexible. Flexible quarter inch drywall can also be used to cover curved walls, curved stairwells and archways and radius ceilings. The thin design makes it easier to bend than standard half inch drywall. And flexible 1/4 inch drywall is covered with heavier, stronger paper than standard drywall is. This makes the flexible drywall easier to bend and more resistant to cracking. Quarter inch drywall used in new construction is usually applied in double layers, with staggered seams where possible. Not all curved surfaces have the same radius—some are broader half circles and some are tighter. For curved surfaces with a shorter, tighter radius of 32 inches or less, wetting the drywall with a damp sponge or roller may be necessary. The moisture helps the thin drywall to bend without breaking. 3/8-Inch Drywall Slightly thicker than 1/4-inch drywall, 3/8 of an inch drywall is also a good choice for curved walls. It’s also used to patch damaged drywall. 1/2-Inch Drywall 1/2-inch thick standard drywall is the most commonly used drywall for new homes. If you don’t specify another type or thickness of drywall for your interior walls, this is what most drywall contractors will use. 5/8-Inch Drywall The thickest drywall that is readily available is 5/8-inch. It is often fire-resistant and a good choice for soundproofing rooms. 5/8 inch is also a great option for ceilings because it helps to prevent the sagging that can occur when standard half inch drywall is used on some ceilings. An alternative to 5/8 inch drywall is half-inch high-strength ceiling panels. Half-Inch High-Strength Ceiling Panels Half inch high-strength ceiling drywall panels are rigid panels with a reinforced gypsum core that resists sagging. Sagging is more likely to occur when using regular 1/2-in. drywall on heavily textured ceilings. There is also a risk of half inch ceiling drywall sagging when ceiling framing components are spaced widely apart. This can happen with advanced framing where studs and joists are spaced 24-in. apart, so called 24 inch on center. In standard framing, remember, components are spaced 16-in. apart or 16 inch on center. To learn more about advanced framing, take a listen to episode 16. The point is that if you put standard half inch drywall on some non standard ceilings, there is a risk of the ceiling sagging over time. So it’s best to use 5/8 inch drywall or half inch high strength ceiling drywall wall. You can also use lightweight half inch drywall for ceiling which is interestingly stronger than standard half inch drywall. We’ll talk more about lightweight drywall in a second. Alright, so that was drywall thicknesses. Now let’s go into the different types of drywall— what the drywall is made of and/or what the drywall is made for. To be clear, different types of drywall may come in different thicknesses. But the information we’re about to cover will help ensure we request the correct category of drywall for our specific applications. DIFFERENT TYPES OF DRYWALL 1. Standard Drywall Standard drywall doesn't have any special features added to the design. It’s simply gypsum board in the middle of two sheets of thick paper. Standard drywall is the most budget friendly option and is the most commonly used drywall in residential construction. It’s suitable for standard walls and standard, uncomplicated ceilings. The rest of the drywall options on our list are generally more expensive, but they are often better choices for specific circumstances that we’ll talk about. 2. Mold and Moisture Resistant Drywall Mold and moisture resistant features a backing or special coating to help prevent the build-up of moisture and mold. It’s often used in humid areas like bathrooms, kitchens, basements, and laundry rooms. There are several different types of moisture resistant drywall. Blueboard is one type of moisture resistant drywall that is easy to find and relatively inexpensive, making it an ideal option for those on a budget. It still requires a water barrier between the blueboard and tile. Greenboard is has similar properties to blueboard, but it’s made of recycled materials. Like blueboard, even though green board is moisture resistant it still requires a water barrier between the green board and tile. Blueboard and green board are older forms of water-resistant drywall. Huge quantities of this product are still being sold, but they are not the best options for the greatest level of moisture and mold resistance. These are the moisture resistant drywall panels that should be used if you’re on a tight budget. Newer forms of moisture and mold resistant drywall are more effective. Look for names such as mold tough, gold bond xp, m bloc and tough rock. Cement board is another moisture and mold resistant option that is the most water resistant drywall available, but it is a more expensive option. Cement board needs to be secured with cement screws not drywall screws. It’s a good idea to install a vapor barrier behind the cement board. This can be in the form of plastic sheets and will help minimize damage if water does make its way through the board. If you’re on a budget, you can choose cement board for the most used bathroom in the house, like a primary bathroom, or the bathroom that is likely to get the most splashes, like a kids bathroom. Then, to save money, you can use green board or blue board for the other bathrooms in the house. 3. Fire Resistant Drywall Fire resistant drywall is made with non combustible glass fibers in an extra-thick design. Sometimes called Type X drywall, fire resistant drywall is ideal for use in utility rooms, garages and areas near a furnace or wood stove. Fire resistant drywall prevents the spread of fire. Plus it generates less smoke than traditional drywall. A bonus advantage of fire resistant drywall is that provides better room-to-room sound control over standard drywall. Building codes may require fire resistant drywall in specific areas of the house or in many areas of the home if you are in a region prone to wild fires. 4. Soundproof Drywall Soundproof drywall is designed to reduce noise from traveling between walls and through ceilings. It’s thicker than most standard drywall sheets and often has two gypsum layers that are glued together with a special noise-dampening adhesive. Soundproof drywalls varies in thickness from 1/2-inch to 5/8-inch. Some soundproof drywall is made with a thin layer of metal sandwiched inside that can further improve sound deadening.For best soundproofing, we should combine soundproof drywall with fiberglass or open cell spray foam insulation. As an alternative to soundproof drywall, which can be fairly expensive, two sheets of standard drywall adhered together can be used. Note that two sheets of drywall will be thicker and take up more space than a single sheet of soundproof drywall. 5. Foil-backed Drywall This drywall has aluminum foil laminated to the back of the panel. The foil adds to the insulating value of the drywall. It is used mainly in cold climates to help prevent interior moisture from entering wall and ceiling cavities. Foil-backed drywall can be used over wood and metal framing or over furred out masonry. It should not be used as a base for tile or highly moisture-resistant wall coverings, such as vinyl wallpaper, because the core could absorb and trap moisture and eventually damage the drywall. Foil-backed drywall is also not recommended for use in hot, humid climates. 6. Lightweight Drywall A sheet of lightweight 1/2-in. drywall weighs in at about 41 lb., compared with 50-60 lbs. for a comparable sheet of standard drywall. The lightweight drywall panels are interestingly tougher and stronger, and are more resistant to sagging that standard half inch drywall panels. Lightweight panels go up into place easier and faster and there is less damage to the drywall edges. Because of the lightweight panels’ superior sag resistance, these lightweight half inch panels can be used for ceilings even if wider framing spacing or heavy texture is used on the ceiling. The lightweight drywall looks, cuts, installs, and finishes the same as regular drywall. The panels are available in all the standard lengths, ranging from 8 ft long to 16 ft long. Lightweight drywall is also available in a 5/8-in.-thick panel. You might be wondering like I was, why lightweight drywall is not always used. Are there any disadvantages to lightweight drywall? Well there are a couple of downsides. Lightweight drywall panels can be more expensive than standard drywall, but that’s not always the case. You may actually be able to negotiate lower labor costs to offset a higher price since the lightweight drywall is easier for crews to work with. The other disadvantage is that lightweight drywall also is not quite as sound resistant as its standard weight counterpart. 7. VOC-Absorbing Drywall Chosen for improved indoor air quality, voc absorbing drywall absorbs volatile organic compounds (VOCs), which cause indoor air pollution. VOC-absorbing drywall permanently removes pollutants from the air. Once the VOCs are captured in the drywall, they are never released back into the air. This type of drywall absorbs VOCs for up to 75 years. This option is best for people who are particularly sensitive to indoor air pollutants and/or those who are want an environmentally friendly option. 8. Abuse-resistant Drywall Abuse-resistant drywall is tougher than other types of drywall. It is made of a reinforced gypsum core and smooth but strong abrasion-resistant paper. Abuse-resistant drywall is also called impact-resistant and high-impact-resistant drywall.

Abuse-resistant drywall is also called impact-resistant and high-impact-resistant drywall. There are some advertisements that claim the panels are as tough as concrete. That is probably somewhat of an exaggeration but they are definitely tougher than both regular and fire-resistant drywall panels. Abuse-resistant panels can be finished like other types of drywall and may be a good choice for garages, utility rooms, home gym, mudrooms and maybe even children’s rooms.

Well, that’s it for out mini lesson. I think we should do a couple of quiz questions to review some key concepts before I let you go. This week we focused on information that will allow you to request the appropriate type and thickness of drywall that will be best for your budget and the functionality of your rooms. In the next mini lesson, we’ll cover drywall design and finish level and wall textures. Whether heavily textured walls or smooth walls are trending and whether bullnose corners are still in style. Make sure you follow the show so that episode goes right to your podcast library as soon as it comes out. Alright, ready for your quiz? QUIZ 1. What is the most water resistant drywall type A. Cement board B. Greenboard C. Blueboard D. Type X Drywall The answer is A. Cement board is the most water resistant drywall. Green board and blueboard are also water resistant, but not are not as effective in preventing moisture damage and mold as cement board. They are however budget friendly options. Type X drywall is not water resistant drywall. Type X drywall is actually another name for fire resistant drywall which is sometime used in garages and utility rooms. 2. True or False. The most commonly used drywall thickness in residential construction is half inch drywall. Thanks true. Half inch drywall is typically used for most interior walls. It’s economical and most drywall installers have experience with half inch drywall. Ceilings with half inch drywall can sometimes sag if the framing has wider spacing such as that used with advanced framing or if heavy texture or heavy insulation is used. So for those ceilings, instead of half inch standard drywall, you can use 5/8 inch standard drywall or high strength half inch drywall or lightweight half inch drywall, which is surprisingly strong. That's it for this lesson. I hope you learned as much as I did. Thanks for stopping by. Please remember that the purpose of this podcast is simply to educate and inform. It is not a substitute for professional advice. The information that you hear is based the only on the opinions, research and experiences of my guests and myself. That information might be incomplete and it’s subject to change, so it may not apply to your project. In addition, building codes and requirements vary from region to region, so always consult a professional about specific recommendations for your home.

0 Comments

Your comment will be posted after it is approved.

Leave a Reply. |

RSS Feed

RSS Feed